Page 1 of 2

iwaver pcb in a zz mt, the cheats method!

Posted: Thu Dec 09, 2004 3:44 am

by betty.k

the biggest mental obstacle in making my zz monster truck propo was installing a servo for the steering. then i thought why bother? the pcb runs a motor so i removed the servo motor and connected the mt steering motor. without the servo pot the motor would run in one direction constantly so i used a resistor in it's place.

the servo pot on an iwaver is 5k ohm so i aimed for a value somewhere in the middle. i found a 3.3k ohm. after centering all the trimpots i wound up with perfect steering in both directions.

if you observe a disassembled servo that's hooked up you'll notice the motor has about 2 or 3 steps in it's speed. so when i turn a little, the motor gently turns the steering and turning hard makes the motor spin at full speed. this coupled with the return spring provides about 2 fuzzy steps of steering each way. i tend to turn at full lock in the rough anyway so it's fine with me.

the throttle control is fantastic! even with the orange motor/gear combo i can lift the front from a standstill or crawl along like a snail with everything in between. i installed 3 x 200mah nimh to power it along

Posted: Thu Dec 09, 2004 7:54 pm

by ph2t

excellent work man! does the steering hold or does the return spring pull it back to centre all the time???

Posted: Thu Dec 09, 2004 8:50 pm

by betty.k

the return spring does it's job well. basically the steering is non propo. but at high speed i can get gentle curves happening.

(i'm trying reeeeeally hard not to call this semi propo!

)

Posted: Mon Dec 13, 2004 9:42 am

by betty.k

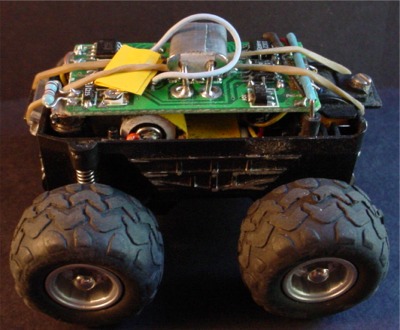

here's some pics. you can see the resistor on the bottom left of the pcb

and it all fits together nicely

there's plenty of room in the bigfoot or jeep body.

Posted: Mon Dec 13, 2004 11:23 am

by codesuidae

Very nice, clever solution to the steering issue.

Any reason the same thing couldn't be done with an SE board?

Posted: Mon Dec 13, 2004 3:53 pm

by betty.k

i can't see why not. with the duty cycle fixed it should work fine.

Posted: Sun Dec 19, 2004 1:20 am

by betty.k

i neatened things up a little and soldered the crystal in to reduce the size. it fits the lower bodies now like my cuda but sadly wizzle willy is still too low for this chassis

i also replaced the steering motor with a red zz motor and it's much better now.

Posted: Fri Dec 24, 2004 7:12 pm

by fook yu

betty.k wrote:i can't see why not. with the duty cycle fixed it should work fine.

You mean a modified SE board or a new model with the better duty cycle? I was just working on one with an SE board, the steering servo was my stumbling block. If I can do without it, then I am almost done. Just gotta decide if I want to sacrifice a fet modded SE or a new SE.

Posted: Fri Dec 24, 2004 7:45 pm

by betty.k

try it out man. this mod is reversible and you still have the option to add a servo later.

Posted: Fri Dec 24, 2004 9:50 pm

by stagg

Im sorry but where would i put the resistor on the SE board??

I may have to try this TOMORROW! lmao.

Posted: Sat Dec 25, 2004 3:29 am

by betty.k

just solder it to the board where ther servo pot wires go.

Posted: Sat Dec 25, 2004 6:32 am

by crazydave

Alright, you cheater, betty, I want to know why this works and how you figured it out.

OK so a potentiometer, or pot for short is a like a variable resistor, and you're just replacing that with a constant resistance. So is it resistance from the pot that determines how far it turns? And I also got confused when I thought about it, because the only pots I know are the ones you turn by hand, like a volume knob. So how does the pot work in a servo?

I'm confused.

Posted: Sat Dec 25, 2004 11:30 am

by Bird

Servo pots are usually little tiny philips-head deals... I find that the little xmod screwdriver is usually perfect for adjusting them...

Posted: Sat Dec 25, 2004 5:34 pm

by betty.k

well i do understand why this works, but i'm not sure i can explain it well.

servos consist of a motor to move it and a sensor pot (variable resistor, pot, volume pot). when you turn the tx wheel it's basically telling the servo where to center. and the more you turn the steering wheel the faster and harder the motor turns, proportional speed. and it's directional, turn the wheel one way and the motor turns one way and vice versa.

so in this setup i get steering because any movement in the steering wheel is translated to the motor, it just doesn't know when to stop as there's no feedback pot connected. instead there's a spring to center the steering.

the steering in this should be considered non propo. even though i get a couple of steps they're unpredictable. and in the rough i tend to steer full lock either way so it's only a problem at speed.

i hope that makes sense, looks like a bunch of gibberish to me!

Posted: Sat Dec 25, 2004 7:41 pm

by crazydave

Nah man, that didn't help me much at all, but thanks for trying.

But but what Bird said helped a little. That sounds like a trimpot. So it sounds to me like the pot is set at a fixed position.

You say that was a 500k pot? I could probably find one at Mouser that's small enough.