Page 1 of 2

HFAY build

Posted: Tue Aug 21, 2007 3:00 pm

by SuperFly

For those that don't know, there is a racing program in Mini-Z land called "How Fast Are You?" or HFAY. I haven't participated yet, but I'm gearing up to do so. You need 2 wide-L RCP tracks (which we have) and a lap timing system (which we need). The gist of it is that a track layout is published, and people all over the place set it up, and submit their best times according to the rules. There's an open class, as well as a "stock" class in which everyone uses stock PCB (single layer 3010 fets) and a motor designed and sold just for this series. The idea being that everyone is racing the same layout with a standardized drive train. I've already got several cars I can run in the modified class, but I needed a "stock" car with the newer 3010 fets (older MR02s have 3004 fets, I believe).

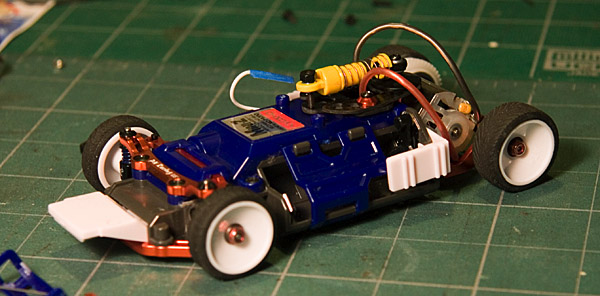

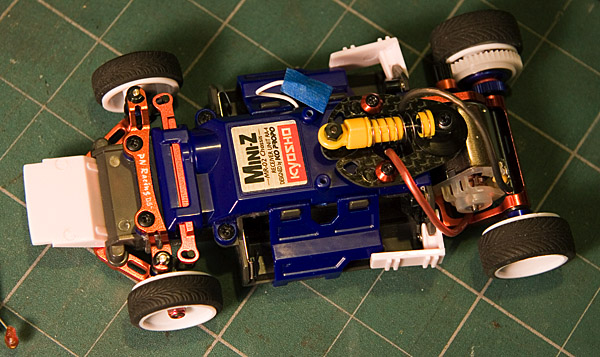

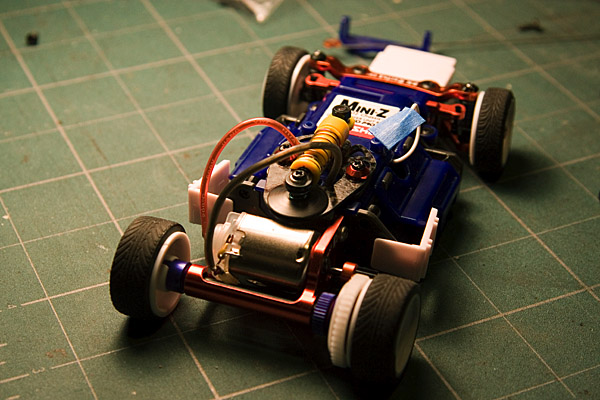

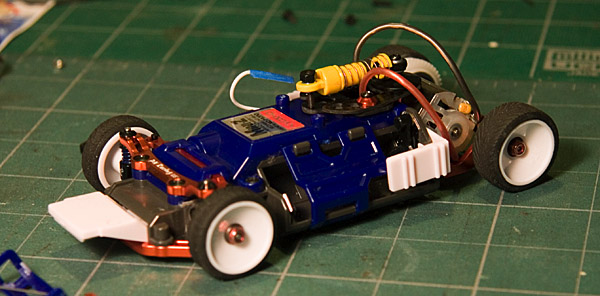

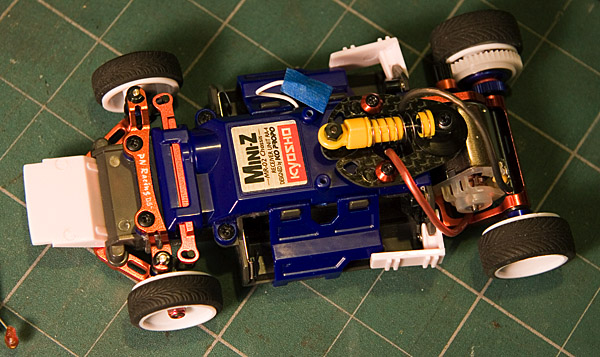

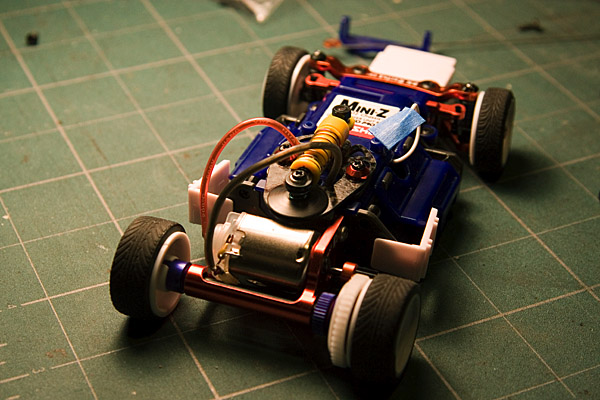

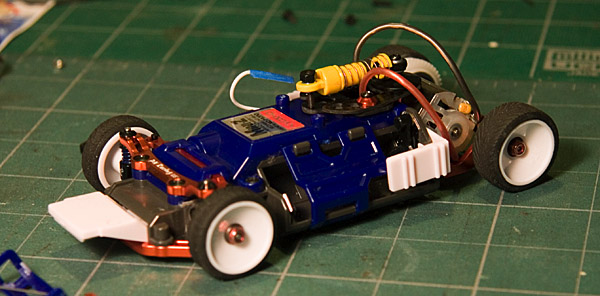

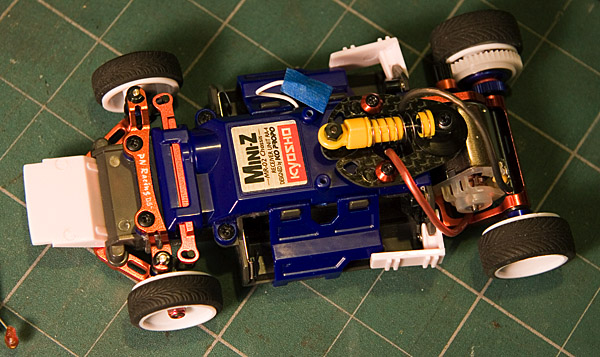

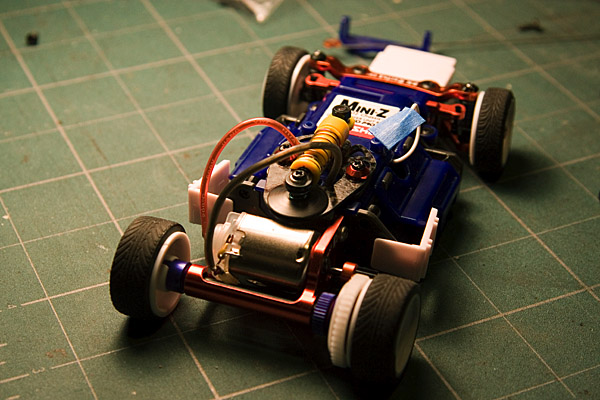

The car I'm building for it is a 94mm mid-mount under a Ferrari 360GTC body. Typically, a MM is 98mm or longer, so this is a RM wheelbase with a MM motor config. Should be the best of both worlds, MM stability with RM agility.

So far, I've got a PN Multi-length motor mount and accompanying disc damper with a Kyosho oil shock on top and a Kyosho ball diff running through it, PN tower and lower bar front end with .5 degree caster, alloy 2 degree cambered knuckles, .5 degree toe-in tie rod, dish wheels and a white body that's getting prepped for fitting and painting.

Sorry for the crappy pix, I just shot them on my dingy worktable rather than setting up all the gear.

Posted: Tue Aug 21, 2007 3:53 pm

by SHAUN

Thats bad ass, can't wait to see it painted. keep up the good work

Posted: Tue Aug 21, 2007 5:08 pm

by payaso

That's sweet man.

That'd be really cool to get into that. The cash for the track is a mofo though...

I remember when they did that for micro sizers too.

Keep us posted on how it goes.

silla

Posted: Wed Aug 22, 2007 12:41 am

by color0

That's a pretty bling chassis, Superfly. Just for shits and giggles or does the aluminum actually help?

Posted: Wed Aug 22, 2007 1:38 am

by SuperFly

Thanks for the compliments, guys. I'll post more pictures as the body treatment develops

color0 wrote:That's a pretty bling chassis, Superfly. Just for shits and giggles or does the aluminum actually help?

There's two alloy things that really don't need to be alloy; the tie rod and the pinion collar.

The alloy motor mount allows much more motor position adjustability for perfect gear mesh, as well as this being the only way to run a MM config with that body. The alloy tower bars replace the weakest part of the chassis and allow for caster adjustment you couldn't otherwise achieve. This is the first mini-z I'll have a chance to experiment with caster settings, so I'll have to check back on whether or not it helps. Alloy knuckles are for strength, I've broken my share of plastic ones.

Though I appreciate bling as much as the next guy, my main goal is to improve performance.

Posted: Wed Aug 22, 2007 3:28 pm

by ynad

interesting set-up

I'm also wandering about caster, does it improve stability?

keep us posted, please

Posted: Wed Aug 22, 2007 3:55 pm

by SuperFly

ynad wrote:interesting set-up

I'm also wandering about caster, does it improve stability?

keep us posted, please

Here's a bit of info on caster, as well as the link to where I got it, which also discusses camber and toe:

THE EFFECTS OF CASTER

Caster is the angle to which the steering pivot axis is tilted forward or rearward from vertical, as viewed from the side. If the pivot axis is tilted backward (that is, the top pivot is positioned farther rearward than the bottom pivot), then the caster is positive; if it's tilted forward, then the caster is negative.

Positive caster tends to straighten the wheel when the vehicle is traveling forward, and thus is used to enhance straight-line stability. The mechanism that causes this tendency is clearly illustrated by the castering front wheels of a shopping cart (above). The steering axis of a shopping cart wheel is set forward of where the wheel contacts the ground. As the cart is pushed forward, the steering axis pulls the wheel along, and since the wheel drags along the ground, it falls directly in line behind the steering axis. The force that causes the wheel to follow the steering axis is proportional to the distance between the steering axis and the wheel-to-ground contact patch-the greater the distance, the greater the force. This distance is referred to as "trail."

Due to many design considerations, it is desirable to have the steering axis of a car's wheel right at the wheel hub. If the steering axis were to be set vertical with this layout, the axis would be coincident with the tire contact patch. The trail would be zero, and no castering would be generated. The wheel would be essentially free to spin about the patch (actually, the tire itself generates a bit of a castering effect due to a phenomenon known as "pneumatic trail," but this effect is much smaller than that created by mechanical castering, so we'll ignore it here). Fortunately, it is possible to create castering by tilting the steering axis in the positive direction. With such an arrangement, the steering axis intersects the ground at a point in front of the tire contact patch, and thus the same effect as seen in the shopping cart casters is achieved.

The tilted steering axis has another important effect on suspension geometry. Since the wheel rotates about a tilted axis, the wheel gains camber as it is turned. This effect is best visualized by imagining the unrealistically extreme case where the steering axis would be horizontal-as the steering wheel is turned, the road wheel would simply change camber rather than direction. This effect causes the outside wheel in a turn to gain negative camber, while the inside wheel gains positive camber. These camber changes are generally favorable for cornering, although it is possible to overdo it.

Most cars are not particularly sensitive to caster settings. Nevertheless, it is important to ensure that the caster is the same on both sides of the car to avoid the tendency to pull to one side. While greater caster angles serve to improve straight-line stability, they also cause an increase in steering effort. Three to five degrees of positive caster is the typical range of settings, with lower angles being used on heavier vehicles to keep the steering effort reasonable.

http://www.ozebiz.com.au/racetech/theory/align.html

So, ideally I'll be achieving a car that wants to straighten itself out once I stop giving steering input, as well as a car that increases the negative camber of the front wheels the more turning input I give.

Posted: Sat Aug 25, 2007 2:11 am

by dogbreathracing

Hey Fly, when you get the counter up let me know, I'm in the series for sure, maybe the other two drivers also. And just for fun we could always add your two wide L's to my two wide L's and have a whoopin' good time on a 4 L track.....

Posted: Sat Aug 25, 2007 2:29 am

by sidewinder

Hey SF, do you have to run a stock based body. There are 1/24 scale slot car wedge bodies that could be adapted. You'd lose some weight and pick up a whole hell of a lot of downforce.

Posted: Sat Aug 25, 2007 9:05 am

by SHAUN

They wont work they sit to low. You could probably fit a nascar to it.

Here is a wing body

Whats the wheel base on the Z?

Posted: Sun Aug 26, 2007 7:09 pm

by ynad

Thank you

@ SHAUN,

The car I'm building for it is a 94mm mid-mount under a Ferrari 360GTC body. Typically, a MM is 98mm or longer ...

Posted: Sun Aug 26, 2007 8:23 pm

by SHAUN

Ignorance at its best I suppose.

Posted: Wed Aug 29, 2007 12:27 pm

by SuperFly

There is a pan car body that you can use under the spec.

I'm not going to do that though, because half the fun of mini-zs is the cool AutoScale bodies you can run. Also, a lightweight lexan wing body like for slot cars would get eaten alive in a multi-car mini-z race. There's a fair amount of contact, and you need the rigidity and mass of a "regular" mini-z body to not get beat to hell.

DBR-

We'll keep you posted on the progress, but we'll also try and plan our next race night ahead enough to invite you down. Lately, we haven't known when we'd be able to race until a couple hours before, but we're going to try and figure out a regular schedule, like 2nd and 4th Friday evenings each month or something.

Posted: Wed Aug 29, 2007 3:13 pm

by BilboBaggins

You might be surprised on the abuse slot car guys can do to those bodies (think NASCAR short track racing.) I've been in a few wreck-fests and the body survived, but the chassis did not.

Posted: Wed Aug 29, 2007 3:36 pm

by guerd87

nice looking mini-z

cant wait to hear more

thats the roblem with those slot car bodys, they are so soft they just let the damage to whats inside the car, in this case...plastic

when i use to race slot cars had a few leave the track and smash the wall, usually breaking motormounts or twisting the thin metal chassis