One down 3 to go MMO alloy wheels

- LBRC

- bitGangsta'

- Posts: 361

- Joined: Sun May 02, 2004 1:25 am

- Location: North West

- Contact:

Sale? Hm maybe, once I get the anodizing and dyeing process down, can consistently turn out sets of 4 matching wheels that I’m not too ashamed of, have enough for my cars, then yes I will try to make some to sell. The “when” part is hard to pin down though I still have a long way to go.

And yet another version.

Dyed red,

Good pic of the ball bearing with pressed axle on the knuckle, with just a bit of lock-tight on the outer bearing rim the wheel stays on nicely and can still be coaxed off if needed, but not easily. Another nice accident is that you can choose how far to press the axle into the knuckle adjusting the wheel offset slightly to match your body.

And yet another version.

Dyed red,

Good pic of the ball bearing with pressed axle on the knuckle, with just a bit of lock-tight on the outer bearing rim the wheel stays on nicely and can still be coaxed off if needed, but not easily. Another nice accident is that you can choose how far to press the axle into the knuckle adjusting the wheel offset slightly to match your body.

- crazydave

- bitPimp

- Posts: 6874

- Joined: Thu Apr 17, 2003 9:05 am

- Location: Koolsville

A nice true wheel with a bearing would be so amazing.

You can definatly add me to the jealous club.

I was thinking, how hard would it be to give it a flat lip around the edge? It would be cool if you could anodize it, then take it off around the lip, with sandpaper or something. I'm figureing the silver around the edge would give the anodizing some contrast.

You can definatly add me to the jealous club.

I was thinking, how hard would it be to give it a flat lip around the edge? It would be cool if you could anodize it, then take it off around the lip, with sandpaper or something. I'm figureing the silver around the edge would give the anodizing some contrast.

- LBRC

- bitGangsta'

- Posts: 361

- Joined: Sun May 02, 2004 1:25 am

- Location: North West

- Contact:

-

sg219

- bitPimp

- Posts: 4244

- Joined: Thu Jan 22, 2004 1:00 pm

- Location: Kennywood, PA

- Contact:

- HirotoR34

- bitPimp

- Posts: 1396

- Joined: Tue Oct 28, 2003 10:17 pm

- Location: in vdubland

- Contact:

- LBRC

- bitGangsta'

- Posts: 361

- Joined: Sun May 02, 2004 1:25 am

- Location: North West

- Contact:

Seemed to me that the rear dish wheels would be a bit heavy if left solid, unfortunately hollowing them out raises the minor problem of mounting the gear in such a way that you can change it if needed.

Trying a couple of ideas but nothing I’m truly happy with yet. Am also experimenting with a stiffer piano wire axle since the ZZ axles have a tendency to bend.

This is just a test rim, but the photo doesn’t do it justice, its pure sex even if I do say so myself, ignore the hole I drilled it all the way through to make it easier to take some measurements.

Another problem is what to do to preserve the finish on a mirror polish bare metal dish, since anodizing changes the color and bare aluminum is too easy to scratch.

Trying a couple of ideas but nothing I’m truly happy with yet. Am also experimenting with a stiffer piano wire axle since the ZZ axles have a tendency to bend.

This is just a test rim, but the photo doesn’t do it justice, its pure sex even if I do say so myself, ignore the hole I drilled it all the way through to make it easier to take some measurements.

Another problem is what to do to preserve the finish on a mirror polish bare metal dish, since anodizing changes the color and bare aluminum is too easy to scratch.

- betty.k

- bitPimp

- Posts: 4090

- Joined: Fri Dec 26, 2003 4:52 pm

- Location: la la land

- Contact:

i understand how polished aluminium is difficult to capture, try putting something in the pic with it.

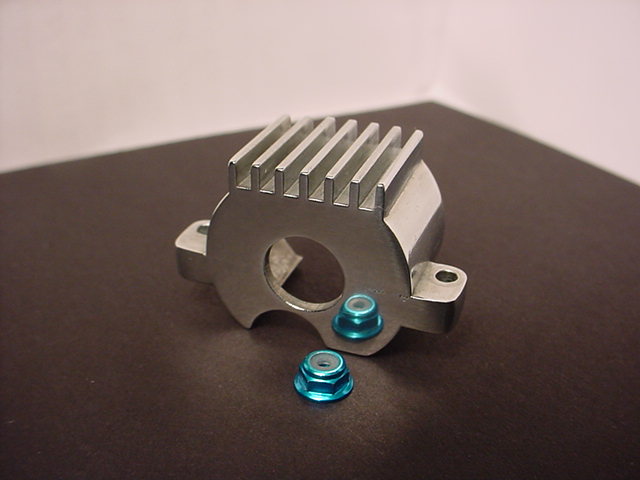

this was all i came up with for my xmod heatsink:

the problem, as you said, is keeping it that pretty. that heat sink would start to look dull within 3 days!

my thoughts are apply a clearcoat of some sort. perhaps a clear epoxy paint

this was all i came up with for my xmod heatsink:

the problem, as you said, is keeping it that pretty. that heat sink would start to look dull within 3 days!

my thoughts are apply a clearcoat of some sort. perhaps a clear epoxy paint

- LBRC

- bitGangsta'

- Posts: 361

- Joined: Sun May 02, 2004 1:25 am

- Location: North West

- Contact:

Have to see what I can find in the way of a hard clear enamal, nice way to show a mirror finish. Was going to try the anodizing sealant step alone today to see if it helped any, but thanks to a blown fuse on the power pole transformer things sort of went to crap.

Important anodizing note; do not leave parts in an acid anodizing take for 8 hours, also if power goes off turn the tank power off that way when it comes back on your parts might have a chance of surviving. Apparently when the parts reach the “dissolution point” the anodized layer can’t grow any thicker and the acid starts to dissolve the aluminum, sort of messes up things like bearing, screw, and axle holes, turning a whole weekends work into scrap metal.

Important anodizing note; do not leave parts in an acid anodizing take for 8 hours, also if power goes off turn the tank power off that way when it comes back on your parts might have a chance of surviving. Apparently when the parts reach the “dissolution point” the anodized layer can’t grow any thicker and the acid starts to dissolve the aluminum, sort of messes up things like bearing, screw, and axle holes, turning a whole weekends work into scrap metal.

-

frizzen

- bitDisciple

- Posts: 1729

- Joined: Wed Aug 03, 2005 7:48 am

- Location: Big Left Turn, Indiana

- Contact:

- LBRC

- bitGangsta'

- Posts: 361

- Joined: Sun May 02, 2004 1:25 am

- Location: North West

- Contact:

Thanks, looks like the Zoop seal or somthing like it might just do the trick.

Power FuPA Casualties:

>3 Epoch motor mounts, motor and bearing holes now enlarged beyond use, screw holes too large for 2-56.

>3 ZZ wheel sets; 6 Rear wheels with axle holes enlarged so that axles are loose. 6 Front wheels with bearing holes that no longer hold bearings tight.

Not devastating, just enough to sort of suck the enthusiasm right out of you.

Power FuPA Casualties:

>3 Epoch motor mounts, motor and bearing holes now enlarged beyond use, screw holes too large for 2-56.

>3 ZZ wheel sets; 6 Rear wheels with axle holes enlarged so that axles are loose. 6 Front wheels with bearing holes that no longer hold bearings tight.

Not devastating, just enough to sort of suck the enthusiasm right out of you.