This thread may be in the wrong section, now that I think about it. (Please move if so

)

OOps. This does need an additional tool, a cutting tool(xacto or similar)

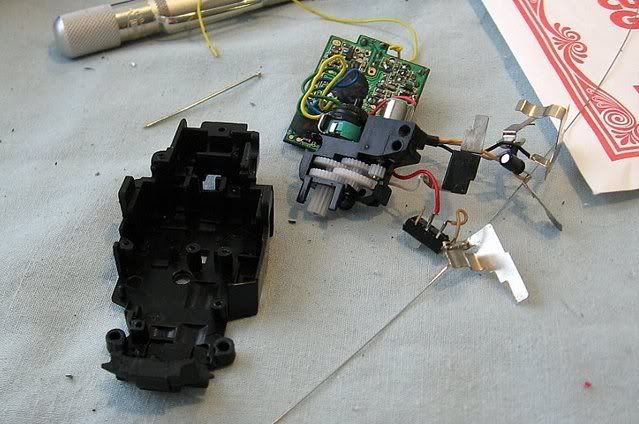

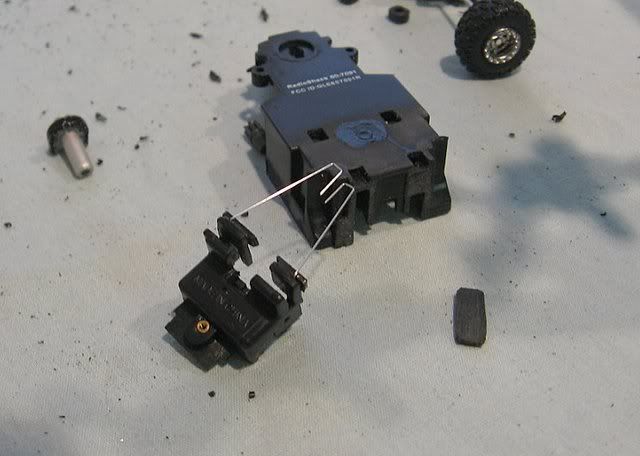

Here is the start.

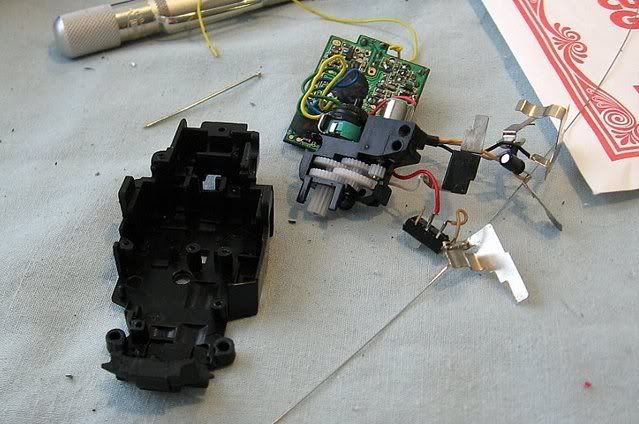

Disassemble the bit zip, or whatever you're modding. I'm using a ZZSE this go around.

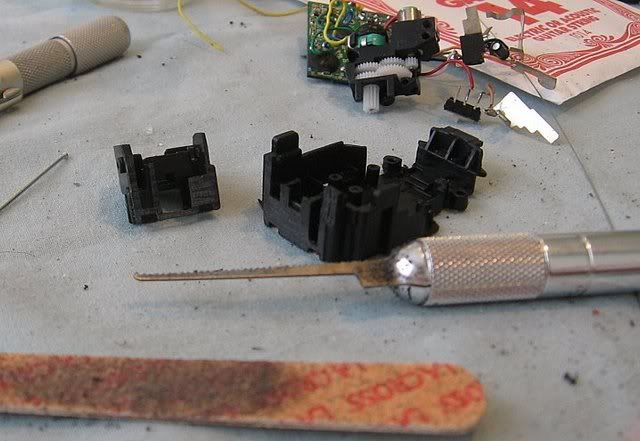

Find a line to cut through the chassis to separate the rear section(motor assembly with the axle all intact). After that file or sand smooth.

Where I cut this one, I had an area on one side of the rear section, that had a void. The ZZ chassis I cut for the Phoenix Zip didn't have it. No problem. Just take the shavings or scrap plastic, dump it in the void. Then using the Bondene or CA, put a dab on the area. With the shavings, it creates a putty like substance. I like this Bondene stuff, because it is a plastic weld, actually melting the styrene or abs plastics and fusing it together. And it cures in 30 minutes, unless too much was used.

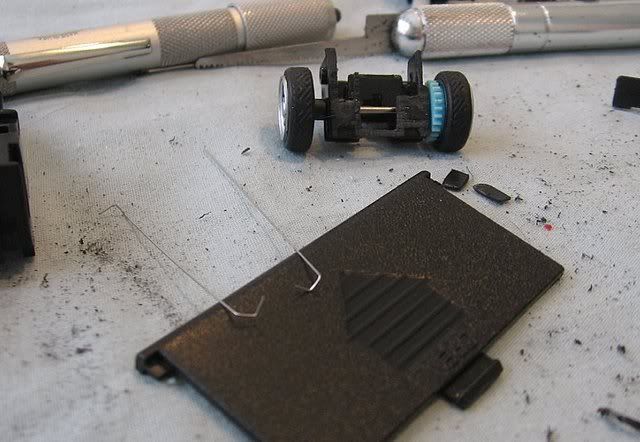

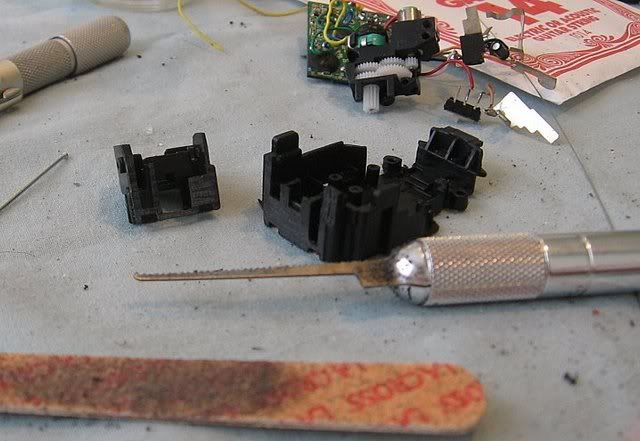

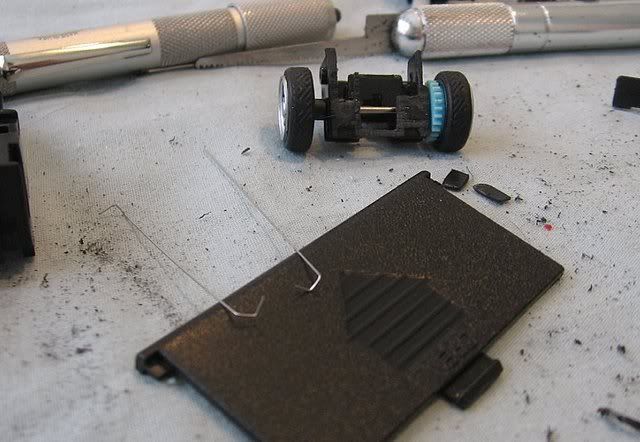

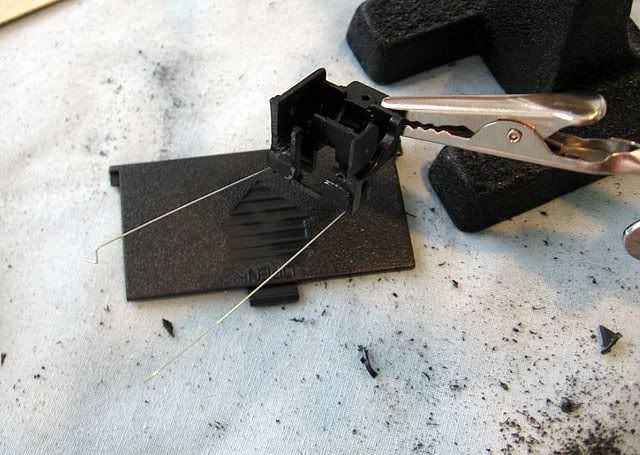

You can see the void filled in in this pic. just needed to be flattened out with a nail file. Take one piece of the the guitar string (pictured is 11 gauge that is thinner than the 14 shown earlier. I wanted a very loose suspension

) and bend the ends into angles. Basically, I made a 90* bend about 3-4 mm from the end horizontally, and another 90* bend about 3-4 mm vertically to the the left (on the other piece of string, bend to the right). At this point, you'll need 2 small thin rectangular flat pieces of plastic. note the ones to the right in the pic.

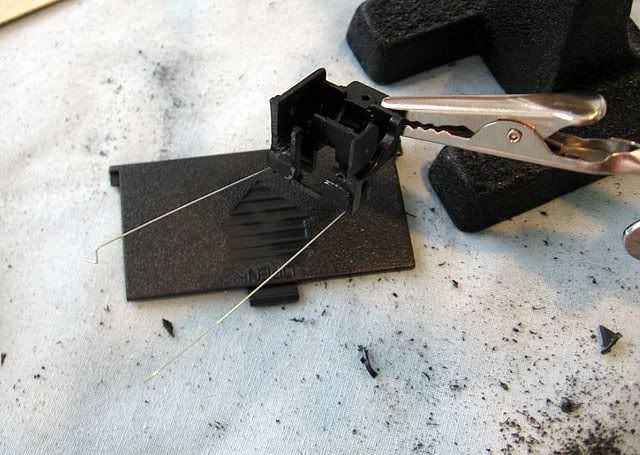

Now you will take the glue and the rear part of the cut chassis, dab some on the area that the string will attach to. Have it so the string is to the outer side and bottom of the foward facing area (not all the way to the edge, though), and so that the "L" shape faces inward, as in the pic. Keep in mind, the center of this section is not exactly the center of the rest of the chassis. So consider that in the placement of the strings. Place one of rectangular scraps, and place it on top of the"L", fully covering it. Press gently for several seconds, to make the plastic bond as well as possible. Don't worry if the strings don't stick out evenly, or are crooked. Once it's cured, they will bend anyway you want them to. The gluing of the "L" in such a way is so that the string will not slide out or come loose later on by movement in any direction.

After it is fully cured, you can trim or sand the edges for a cleaner look. And you can then bend the string to the desired direction. Just don't go crazy with it, it will break if you keep bending it back and forth, just like any metal.

Next up will be mating the chassis back together......but not now.

And it has opened the door to the front suspension issues that have kept me from finishing my OffRoadSE.

And it has opened the door to the front suspension issues that have kept me from finishing my OffRoadSE. And the only tool it will require is old nail clippers (or cutting dikes) and a very small set of needle nose pliers.

And the only tool it will require is old nail clippers (or cutting dikes) and a very small set of needle nose pliers.