Page 1 of 3

WheelyKing Project

Posted: Thu Jul 19, 2007 10:41 pm

by SHAUN

Well, I have been working on this for almost a month now. I just finished it yesterday 7/19/07.

Heres a list of what I have put on the truck.

Traxxas 108mm tierods (4)

Traxxas 125mm tierods (4)

Traxxas halfshafts

Junfac 2.2 MudRock Beadlocks

TCS Steel Lockers

R&R 48P 14t Pinion

I have put a lot of work into this truck, I will be running my first comp on the 21st at Disney, Oklahoma.

You probably don't want to hear my shitty grammar anymore, you just want the pics. Here they are.

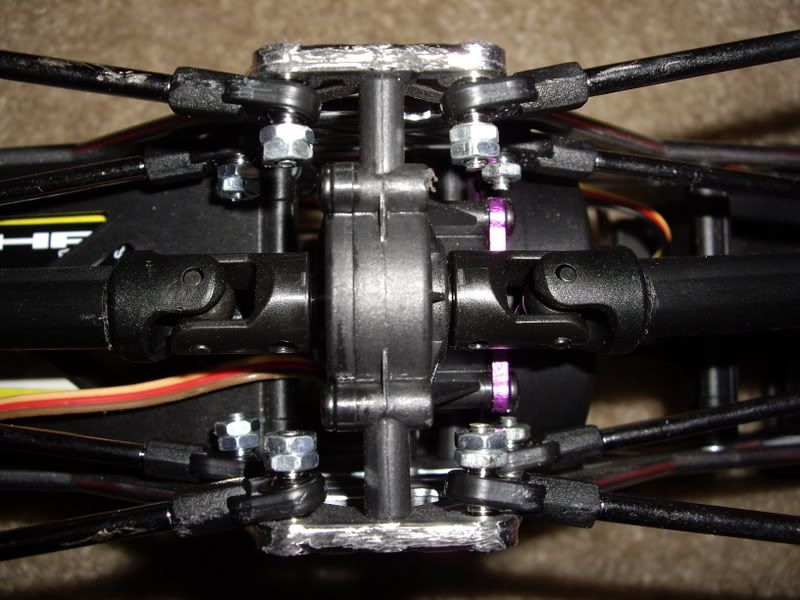

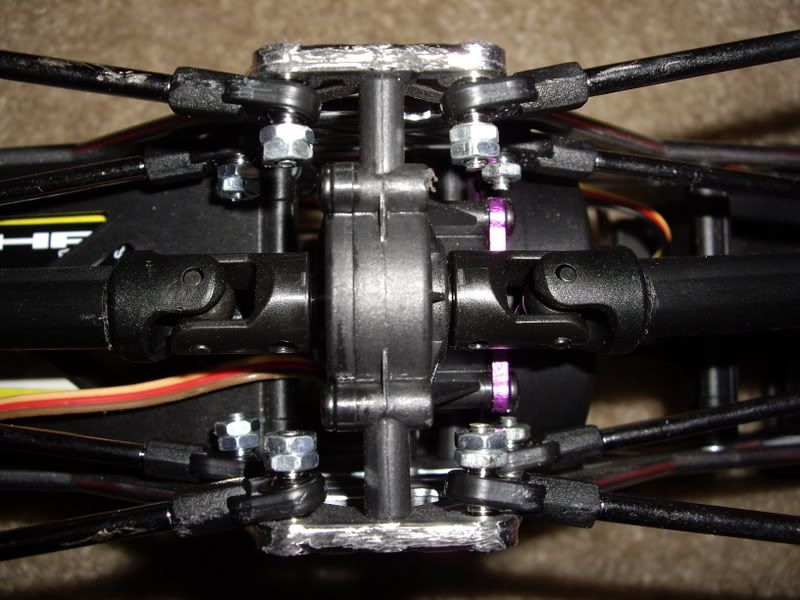

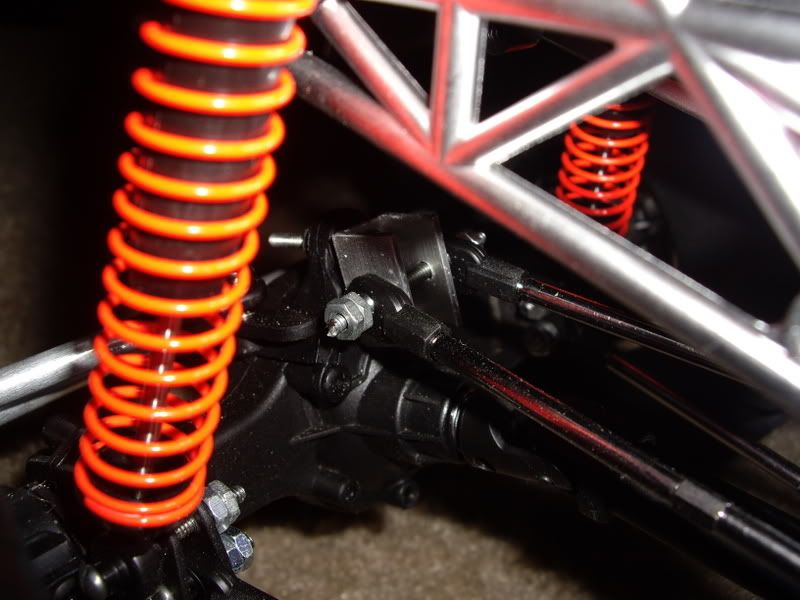

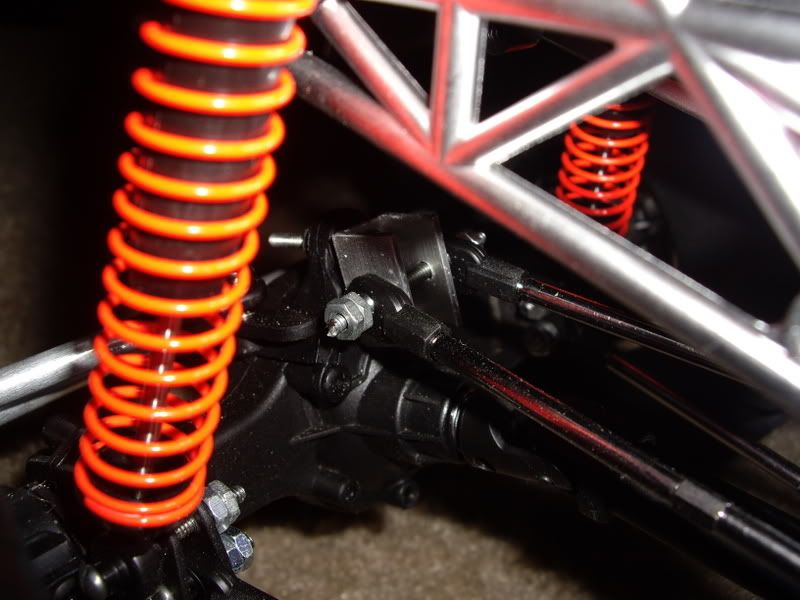

Heres my rear lock out, the stock one was week.

Had to fab up a few parts, no biggie

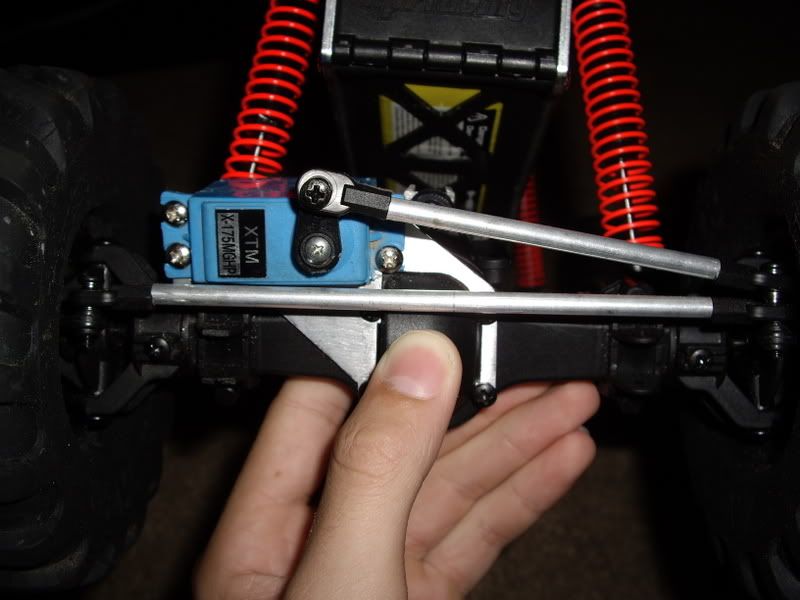

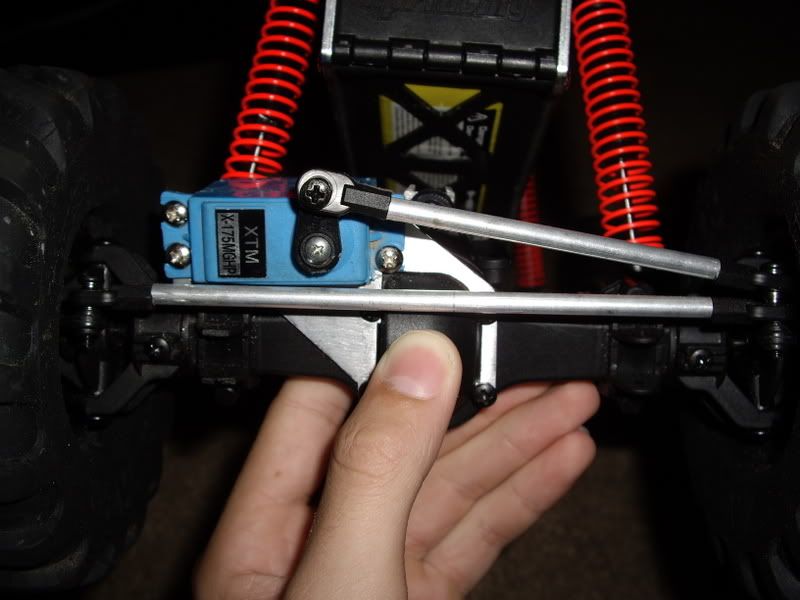

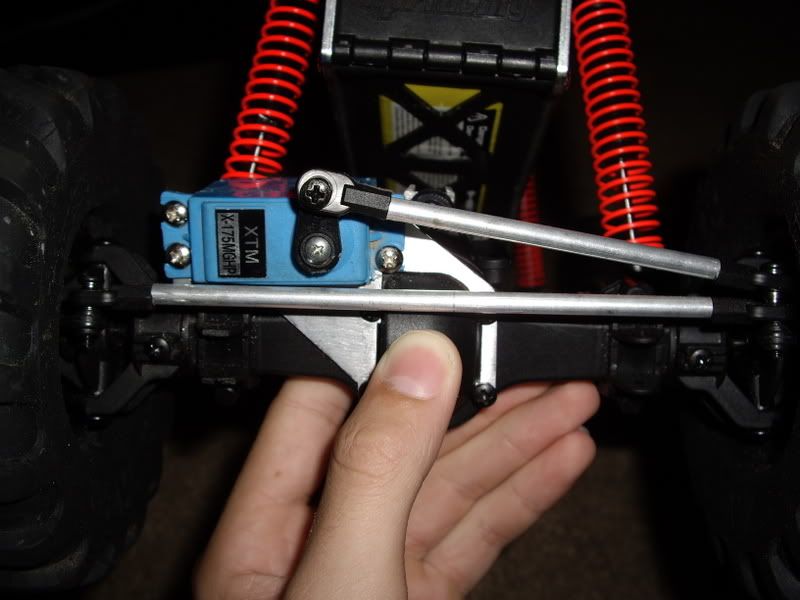

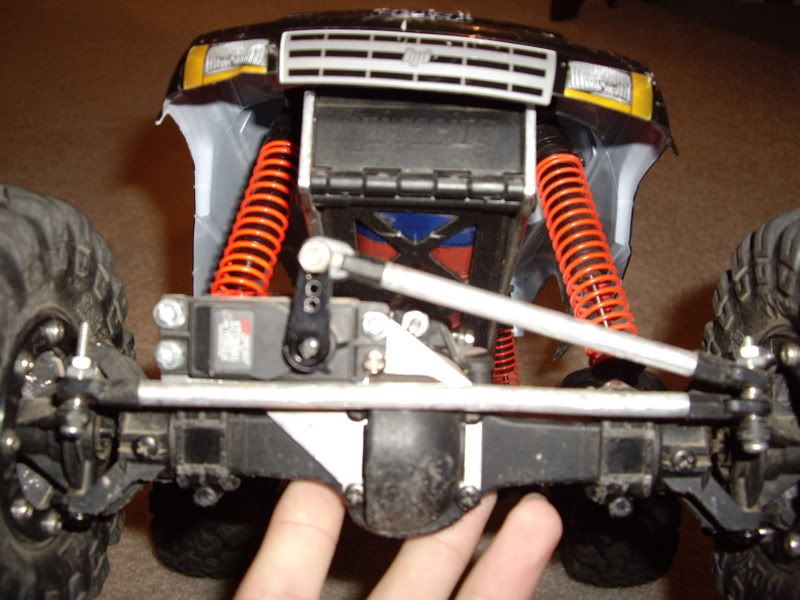

My servo mount, thanks mrmaxxman

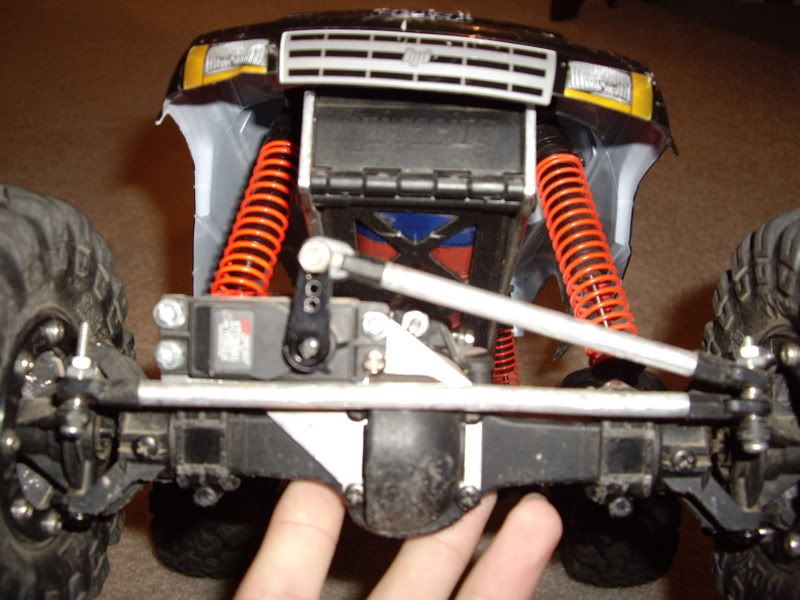

Maggie likes flex apperently

The Junfac 2.2 MudRock Beadlocks

The pitbox, yes I know the radioshack charger is a POS I'm getting a different one soon.

Thanks for looking comments welcome.

Posted: Fri Jul 20, 2007 1:16 am

by guerd87

looking good shaun, what size motor are you running?

ive got a few spares hours on the weekend so im going to do some work to my e-savage axles and i will be posting that up soon

got any pics of it on the rocks yet? want to see how it flexes

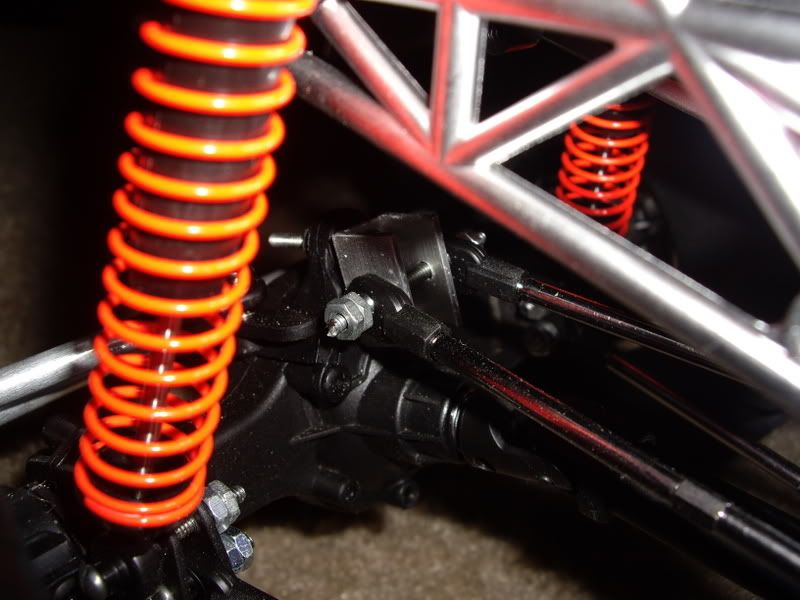

question: how do you find the shocks being vertical? i found i couldnt get a whole lot of good usable flex with mine unless they were on around a 45 degreee angle?

John

Posted: Fri Jul 20, 2007 1:31 am

by SHAUN

45 degrees is good for shocks, this isn't finished after this comp it will be getting a tube chassis, I really don't have anything else to do with the shocks right now. motor is 540, I will be running a 55t lathe at the comp along with lizards on the junfac beadlocks.

Just changed the shock to mount on the inside of the shock tower, works great not to much more angle but the suspension will flow better.

Posted: Fri Jul 20, 2007 10:36 am

by crazydave

I was originally planning to reverse my chassis like that, but decided that's something that I can always do later if I ever really ever get to take it out to crawl. Its not very difficult is it? Did you just reverse the motor wires, to get it to go the other direction?

I was also going to do the rear steering lock out like that, but when I actually had the truck in my hands I saw that little shelf has quite of bit of flex in it. Didn't seem right to me to make the rest of the assembly more rigid and put all the flex on that little piece. You're gonna have to let us know how well that holds up.

Oh yeah, and what's your wheelbase after the stretch? I was just gonna aim for around 12.5" since I read that was the max legal in competition.

Man, I hope mine isn't on the bench for a month. That's why I went with the WK over the TLT, because I want to play while I modify.

Posted: Fri Jul 20, 2007 11:37 am

by SHAUN

Most of my sitting was because

1) We're moving

2) Had to wait for parts

3) Slot cars take up a lot of my time

It was easy to do the flip, if you decide to go the servo mounted on axle way, just put the lock out on the front axle and put the servo on the rear axle. Flipping the motor wires is required. The flip makes a world of difference on the rocks.

I also ordered a bunch of fasteners from mcmaster.

Pack

90272A113

Zinc-Pltd Stl Pan Head Phillips Machine Screw 4-40 Thread, 3/4" Length, Packs of 100

$2.05 Pack

$2.05

Pack

90272A114

Zinc-Pltd Stl Pan Head Phillips Machine Screw 4-40 Thread, 7/8" Length, Packs of 100

$2.09 Pack

$2.09

Pack

90272A115

Zinc-Pltd Stl Pan Head Phillips Machine Screw 4-40 Thread, 1" Length, Packs of 100

$2.33 Pack

$2.33

Pack

90631A005

Grade 2 Hex Nylon-Insert Locknut Zinc-Plated Steel, 4-40 Screw Sz, 1/4" W, 9/64" H, Packs of 100

$2.23 Pack

$2.23

Pack

90633A005

Grade 2 Hex Thin (Jam) Nylon-Insert Locknut Zinc-Plated Steel, 4-40 Screw Size, 1/4" W, 7/64" H, Packs of 100

$2.15 Pack

$2.15

Pack

90279A115

Znc Pltd Stl Round Head Phillip Machine Screw 4-40 Thread, 1" Length, Packs of 100

$5.81 Pack

$5.81

Pack

90272A153

Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 1" Length, Packs of 100

$2.62 Pack

$2.62

Pack

90633A007

Grade 2 Hex Thin (Jam) Nylon-Insert Locknut Zinc-Plated Steel, 6-32 Screw Size, 5/16" W, 1/8" H, Packs of 100

Posted: Fri Jul 20, 2007 4:34 pm

by guerd87

how come you guys arnt running 4WS? comes in handy on the rocks,great for sharps turns etc too heehe

done some work last night and my baby comes in at around 17" wheelbase, this thing is wide as all hell

E-Savage diffs with 40series moabs

Posted: Fri Jul 20, 2007 10:27 pm

by SHAUN

4WS is not allowed on comp vehicles only supers. How ever a DIG is allowed, I will be coming up with a dig soon.

Posted: Fri Jul 20, 2007 10:48 pm

by sg219

SHAUN wrote:4WS is not allowed on comp vehicles only supers. How ever a DIG is allowed, I will be coming up with a dig soon.

SHAuN's idea of dig....

I miss my 4WS...

Posted: Sat Jul 21, 2007 12:06 am

by SHAUN

Hey!!! How did you find that out! I have done a few things to the truck.

Added weight to front wheels (Junfac beadlocks, not the stock ones)

Replaced hardware with pan head phillips screws and nylon insert nuts.

I had to beef up the steering alot, I had a highspeed crash and ripped the

servo out of the mount. Replaced hardware with 4-40 machine screws.

Can't wait till tomorrow get to meet a bunch of great guys and see some bad ass rigs. Maybe even learn a thing or two, but now its time for sleep. Have to get up at 4:00am

.

Posted: Sat Jul 21, 2007 7:03 pm

by guerd87

ok then thats no problem, i run in the outlaw class here in aus where anything prettymuch goes, i dont think you cna have 4ws on a 2.2class here but yous looks bigger then 2.2

are you going to buy a premade rear d/c gearbox or building something for yourself?

Posted: Sat Jul 21, 2007 9:26 pm

by SHAUN

Not sure yet. I just got back from the comp, placed 7 out of 10 people, everyone started and everyone finished. Great day didn't break a thing. Also rockedupricky from RCC is so nice, he let me keep the 65t lathe and the brand new Lizards! Said he wanted to help me get started, I really can't thank him enough. I probably could have made it through the whole day with one batt. But in the second round I swapped for insurance.

Posted: Sun Jul 22, 2007 1:19 am

by sidewinder

OK you lost me...but, I like the dog.

Posted: Fri Aug 17, 2007 10:40 pm

by SHAUN

Thanks for the comment about my pup, she is a miniature dachshund, 2 1/2 years old, long hair, and red.

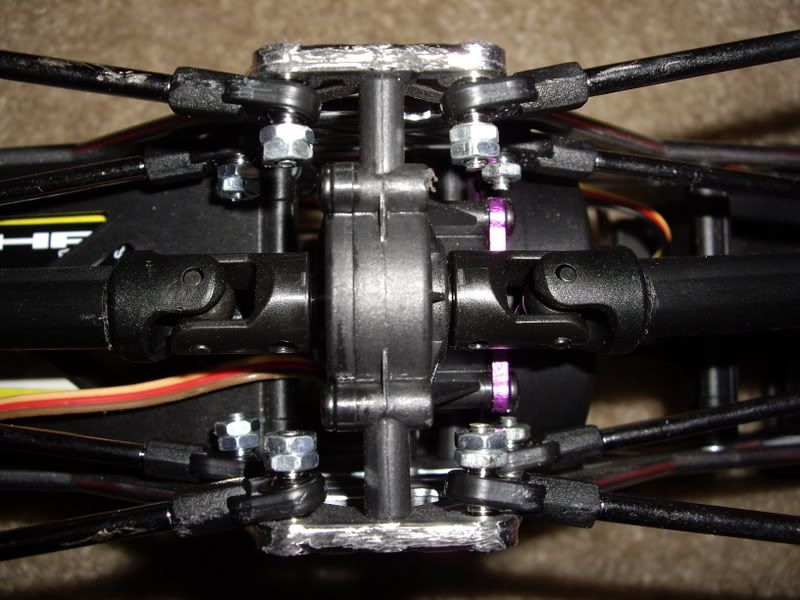

I have a few small up dates. I have trimmed the link mounts, installed the Traxxas u-joints(hpi ones kept popping out), dynamite aluminum servo horn, and beefed up the steering a little bit more.

My XTM servo broke, not wanting to spend the money on a new case for a shitty servo. I got a JR sport ST126MG servo, high torque and metal geared, puts out 126oz/in torque. It does one hell of a job turning them wheels. I wish I could have gotten one of those tower pros that SG had, but I was on my way out to my brothers, so I had to get something that minute.

I broke a shock shaft and I'm in need of a new one, for the time being I robbed one from one of my rustlers. but its a little short. I have also invested in a pretty nice charger I got a Superbrain 960, it does what I need it to do. I need some help with one of the features, more with that later.

Here is a few pictures for you.

Now with the charger, Why would I want to set the delta peak threshold? And for say a 1500 nicd 6 cell stick what would I want to set this at? Will changing any of this affect battery life?

Thank you for reading,

Shaun

Posted: Sat Aug 18, 2007 9:16 am

by crazydave

Looking good.

You need a kick ass body. A kick ass body always makes the car for me.

Posted: Sat Aug 18, 2007 9:22 am

by SHAUN

Yeah, I can't decide between the land rover, bronco, or bushwacker(FJ 40)

Probably wouldn't go all extreme scale on mine but this one is hot.